-

Mr HIPSTER _ Anticonformismo / orecchino

$ 37,57 -

Mr HIPSTER _ Anticonformismo / collana maxi ciondolo

$ 42,93 -

GEM THE STAR _ Luce / orecchino

$ 37,57 -

ROCCIAFIORE _ Roccia / complemento d’arredo

$ 37,57 -

GLOBOFIORE _ Terra / complemento d’arredo

$ 37,57 -

LILIUM ANTICO FIORE _ Purezza / orecchino

$ 37,57

-

CHIAVE DI CUORI _ Appartenenza / orecchino

$ 37,57 -

PRIDE OGM / felpa

$ 206,07 -

ZAMPINO _ Provvidenza / collana maxi ciondolo

$ 42,93 -

CUORE DEI CUORI _ Amore / orecchino

$ 37,57

Riproduci video

GIOIELLI

Dall’ alluminio riciclato nasce un pianeta di gioielli dalle forme divertenti e surreali. Incontra anche tu tutti i personaggi che aiutano OGM nel suo viaggio alla scoperta di OGM PLANeT. Esplora il sogno!

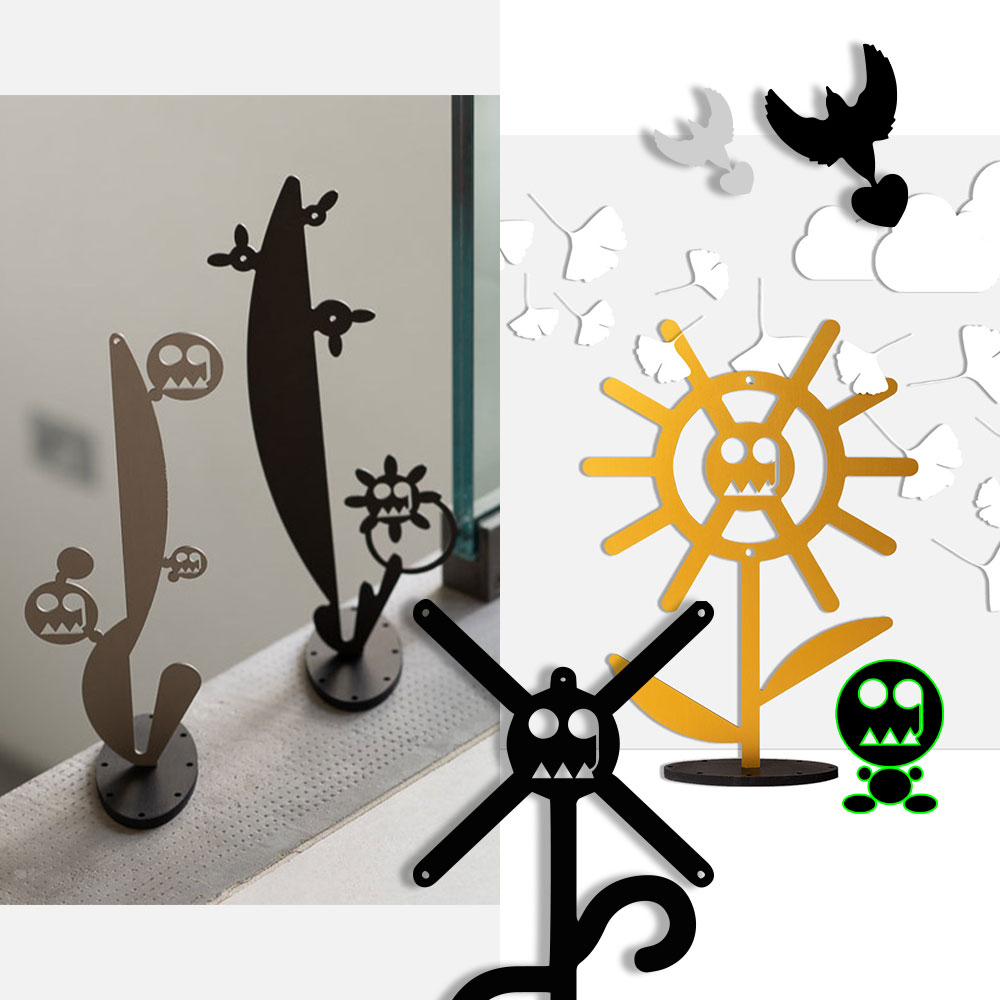

HOME DÉCOR

I protagonisti della favola di OGM PLANeT prendono vita in alluminio riciclato come oggetti decorativi. Per rendere la casa un luogo magico!

Della collaborazione tra CODICEICONA e OGM PLANeT nasce ALBARELLA. La lampada lanterna!

STREETWEAR

La creatività di OGM si veste di tanti personaggi. Felpe in cotone organico e patches in filo di alluminio riciclato. Indossa quello che più ti rappresenta!

Spedizione gratuita sopra 35€

Spedizione gratuita sopra 35€